Increasing ferronickel particle size from the carbothermic reduction of saprolitic nickel ore mixtured with iron ore

DOI:

https://doi.org/10.13133/2239-1002/18020Abstract

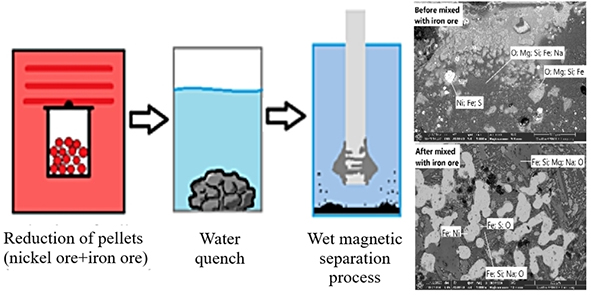

Saprolite has higher nickel content than limonite. Nevertheless, iron and nickel in saprolite are associated with magnesium silicate structures resulting in lower reducibility, indicated by the presence of small particles of ferronickel in reduced ore. Thus, it results in a low recovery of nickel. Iron and sulfur play an important role in increasing the particle size of ferronickel due to the generation of the liquidus Fe-FeS phase, which could promote the agglomeration of ferronickel particles. Therefore, it is necessary to study the effect of mixing saprolitic nickel ore with iron ore in a selective reduction process to increase the ferronickel particle size and its effect on nickel content and recovery. The reduction process of a pellet composite comprising nickel saprolite, iron ore, coal (as reductant), and sodium sulfate (as additive) was carried out at 1150 °C for 60 minutes in a muffle furnace continued with rapid cooling by water quench. The reduced pellet was ground into less than 74 μm. The magnetic separation was carried out to obtain concentrate/magnetic particles (ferronickel) and tailing/non-magnetic particles (impurities). The research reported that mixing saprolite with iron ore could enlarge the ferronickel particle size in reduced ore due to enhancing the generation of troilite (FeS), which promotes the agglomeration of ferronickel particles. It increased the nickel and iron recovery but reduced the nickel content of ferronickel.

Downloads

Published

Issue

Section

License

Copyright (c) 2023 Periodico di Mineralogia

This work is licensed under a Creative Commons Attribution 4.0 International License.