New strategy in Chromium extraction: high efficiency without Chromium

DOI:

https://doi.org/10.13133/2239-1002/18866Abstract

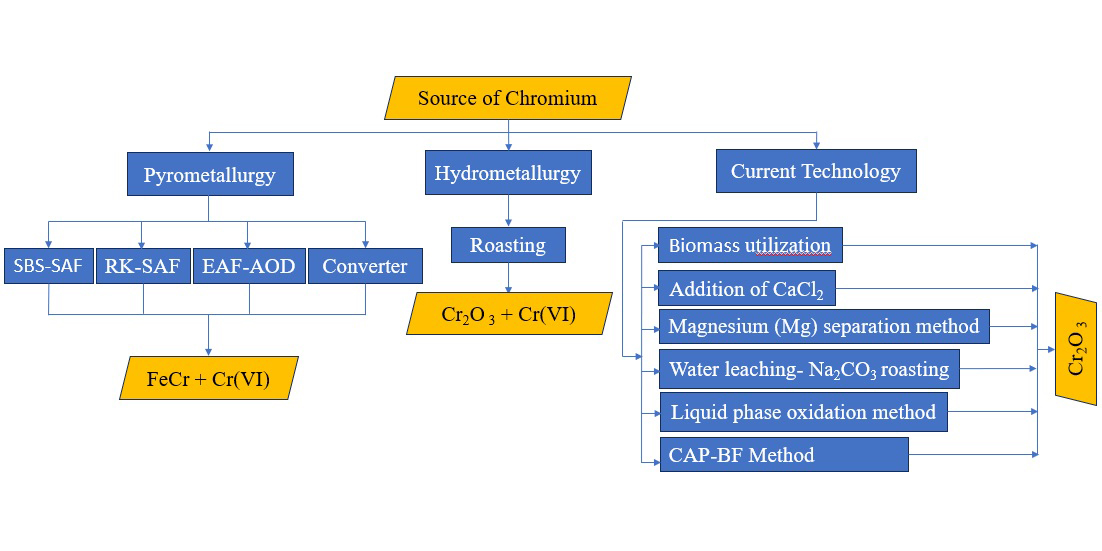

Chromium (Cr) is a very important metal. In nature, Cr is present in chromium ores and the most important part is chromite. Chromite processing is done using pyrometallurgical and hydrometallurgical technologies. Pyrometallurgical technology is generally done by extracting Cr into Fe and chromium alloys called FeCr and other alloys, while hydrometallurgical technology is generally done by extracting Cr into chromite oxide. In general, Cr extraction is done by 2 methods, namely aluminothermic and electrolytic methods. This shows that Cr metal is obtained through hydrometallurgical technology which is then carried out with pyrometallurgical technology in the aluminothermic process. The latest Cr extraction technology generally uses slag or waste that still contains Cr. Based on considerations regarding the increase in Cr extraction and Cr(VI) produced, the most appropriate method is liquid phase oxidation in chromite ore leaching because it is able to produce Cr extraction up to 96% without producing chromite ore processing residue (COPR) containing Cr(VI), making it possible to utilize COPR directly.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Periodico di Mineralogia

This work is licensed under a Creative Commons Attribution 4.0 International License.