Optimization of feldspar grinding parameters for unlimited processing: Case of Algerian feldspar

DOI:

https://doi.org/10.13133/2239-1002/18869Abstract

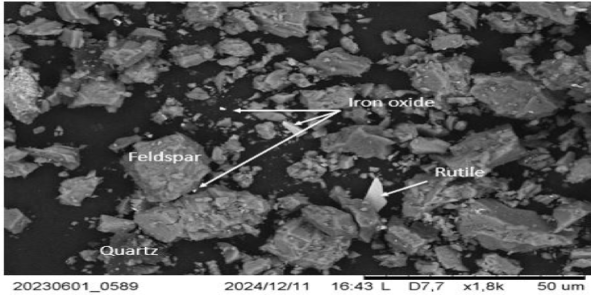

Ore grinding is an essential step in mineral processing, which aims to reduce ore dimension and improve recovery in separation stages. An excessive generation of fines during grinding of feldspar ore frequently limits its treatment. Most of the previous studies have focused on the analysis of ultrafine particles to allow for treatment by flotation or leaching, which costs energy and is not environmentally friendly. the present study aims to increase the yield of potash feldspar in a coarser size range (-0.5 to +0.063 mm), allowing the use of alternative, cleaner, and less energy-consuming processing techniques by optimizing the grinding parameters. Optimal recovery of feldspar using physical separation methods was achieved by modifying ball mill parameters according to particle size and employing Response Surface Methodology (RSM) for particles ranging from 0.5 mm to 0.063 mm. The results present a proportional relationship between weight yield and grinding time; the optimum conditions were 16 minutes of grinding with an 82.5% filling charge. The study demonstrated that feldspar ore needs similar grinding time to attain an equivalent particle size, despite if the process proceeds dry or wet, indicating no difference in grinding performance between the two modes. The ratio of fine particles markedly escalates with extended grinding, underscoring the importance of optimizing and controlling grinding time to avoid overgrinding and ensure effective size reduction.

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Periodico di Mineralogia

This work is licensed under a Creative Commons Attribution 4.0 International License.